Brewing raw ale in Hornindal

Farm by Hornindalsvatnet (Lake Hornindal) |

I tried a Hornindal raw ale at a tasting with friends, and was blown away, for two reasons. The first was that the flavour was nearly indescribable. The second was that it was so good! The consensus was that it felt like a step up from the Cantillon we had before it, and the top-notch Belgian we had after it felt like a step back down. So this really was a world class beer, fit to compete with just about anything.

I got in touch with the brewer on Facebook and tried to figure out how he brewed. Unfortunately, that didn't really clear things up very much. NCYC analyzed his yeast and found that it contained 8 strains of yeast, some not related to one another, plus bacteria. We tried to brew the beer despite not having a full recipe, and split the wort so that we fermented part with his yeast with bacteria, and another part with only his yeast (and no bacteria). That part of the flavour turned out to be due to the bacteria was quite a shock.

One thing I had learned was that the beer was a raw ale. This was no surprise, because the farmhouse ale survey showed very clearly that this was a raw ale region. All along the Sogne fjord and in Voss and Hardanger to the south people boil their ale. Sogn, however, is divided from Nordfjord by the Jostedal Glacier, the biggest glacier in continental Europe. Very likely it was this geographic divide that caused the two regions to develop different brewing processes.

The traditional brewing is still very much alive in the Nordfjord area, but the beers and their brewers had so far proved elusive. This was the only raw ale from that area I'd ever tried. So I decided I would have to visit the brewer, to observe him at work, in order to learn the process. A little persistence finally earned me an invitation, so I booked a flight and a rental car, and set off.

The brewhouse (note the opening Terje cut near top to let the smoke out) |

Terje Raftevold comes from Hornindal, which is where his uncle taught him how to brew when he was 16. Now he lives in Innvik, about an hour's drive away. A local farmer has a brewhouse that he lends Terje, in return for some of the beer. The brewhouse is old, but restored, so that the only original parts left are some old wooden beams, the big stone fireplace, and the copper kettle. A curious detail is that it's built directly on top of a stream. Some concrete steps inside lead down to the stream, in case you want water. This was actually quite handy.

Coming along for the brew session is Roger, a local modern home brewer who is interested in the traditional brewing.

Heating the infusion |

The first step was the same as always: fill the kettle with the garden hose and get a fire going underneath. Meanwhile, Terje cut the juniper that was already gathered, taking the smaller branches. They went into the kettle where Terje boils the juniper infusion. Boiling the infusion definitely changes the flavour of it. He also uses a little less juniper than many others, which turns out to be important. Our first attempt at recreating the beer failed in part because we used too much juniper.

Anyway, while the juniper infusion heated there was time for a break.

Coffee break. Roger left, Terje on the right |

Once the juniper has boiled a little bit, Terje moves over a big blue plastic tun. A good amount of juniper infusion is splashed into the tun, then left to cool. After a while Terje brings over another tun, and a sack of malts. Some malts are poured into the tun. Then he takes a bucket of infusion, pours on, and starts stirring. This is repeated a few times.

Terje then straightens up, and leaves the tun. I bring out my thermometer and rush over, taking its temperature. 73.4C. Whoa! That's hot for mashing, although not really abnormal in farmhouse brewing. It turns out Terje wasn't quite finished, though. He comes back, and repeats the adding of juniper infusion several times, adding more malts, too. Eventually he finishes, and I measure again. 73.8C. Huh. Perhaps he doesn't need a thermometer?

I tell Terje that 73-74 degrees is very warm for mashing. Well, he says, maybe he mashed a couple of degrees warmer now, since it's summer and warm inside the brewhouse. Later, in mid-December, Terje brews his Christmas beer (it's the same beer, really) wearing a boiler suit and a headlamp. Roger brings a thermometer. Terje does his usual mashing with the bucket, and once he's done Roger sticks the thermometer in. 74C. So Terje really doesn't need a thermometer.

Mashing |

Once finished, Terje replaces the lost juniper infusion in the kettle with cold water from the garden hose. "So how long are you going to mash," I ask. "Until the kettle starts boiling again," is the answer. That turned out to be an hour and a half, so we have another break.

Suddenly Terje brings out a long piece of wood with lots of holes drilled in it. "We call this a 'rustekuse'," he says, with an embarrassed grin. The first part of the word is the western Norwegian dialect word for the strainer (lautering tun). The second part is pretty rude. It turns out to have a more polite name, too: "rustesko", with the second half this time meaning "shoe".

Disinfecting the rude thing |

It turns out to be laid directly over the tap in the strainer (rost), to serve as a filter. Then, Terje got a bunch of juniper branches, but did not put them directly into the strainer. Instead, he took a bucket of scalding hot infusion. This was used to dip each branch into, before laying it on the bottom of the strainer as additional filter. As it came up from the bucket, each branch took a cloud of steam with it.

Laying the rost |

I'd never seen this before, so looking at the photos months later, I wondered why. After a while I realized: Terje doesn't boil the wort. So after mashing, at the end of the running, the wort will pass through these branches, be cooled down, and then go into the fermenter. Any bugs on these branches will most likely make it alive into the fermenter, so of course they have to be sanitized.

This, by the way, is a recurring feature in farmhouse brewing. The brewers keep doing things that superficially appear weird, or even detrimental to the beer. On closer examination, however, it nearly always turns out that there are very good reasons for what they do. Occasionally, some practice turns out to be mere superstition, but the same can be said for commercial brewing.

Once the kettle was boiling again we did the same trick as before: scoop infusion over into one of the big blue tuns. Then it was allowed to cool there for a little while before being used. At this point I measured the temperature of the mash again: 74C. While the infusion was cooling we transferred the mash into the strainer, and got it set up. Then we were ready for the running.

The running |

Terje ran off very slowly into big milk cans. The whole process must have taken about six hours, with additions of juniper infusion as necessary throughout. This effectively amounts to a second mashing at lower temperature, but this time the temperature was just about impossible to measure, as it varied widely with time, and also from top to bottom.

Since Terje doesn't boil he can't add the hops during the boil. Instead, he puts the hops into a cloth bag which he drops into the milk can so that the hot wort runs through it. Apparently, old wooden strainers from Hornindal typically have a hook on the tap, for hanging the hop bag from. So the hops are not boiled at all.

Usually, Terje uses hops from the pharmacy. The type and alpha acid content is not known. A local modern home brewer, who is also a bodybuilder, apparently with somewhat unstable moods, met Terje in the shop. Terje is known locally as a veteran brewer, so the guy asked Terje what hops he uses, and how much alpha acid they've got.

"I don't know," says Terje.

"Of course you know, man," shouts the other. "It says right there

on the label!"

Terje has to spend some time calming him down and explaining that he buys his hops at the pharmacy, where they don't list either the type or the alpha acid content. The guy leaves, shaking his head in wonder at this unprofessional old-school brewer.

The hop bag |

This time Terje couldn't get the pharmacy hops, so we're using 300 grams of Saaz hops for 120 liters of beer. If Terje boiled the hops for an hour we'd get 10 theoretical IBUs. This for a quite sweet beer of 7.5%. Terje, however, doesn't boil, so the IBU is zero. Which made me wonder: if we get essentially no bitterness, no aroma, and no protection against infection, what is the point of using hops at all?

Tasting the wort it's clear that there is actually hop aroma, although I think most of it comes from hop particles that settle out during fermentation. In the finished beer there's basically no discernible hop aroma. Per Buer's experiment showed that even unboiled hops deter bacteria. This turns out to be because other substances in the hops besides just alpha acids inhibit bacterial growth. So again we find that while basic brewing knowledge makes it seem as though some farmhouse process is misguided, in practice it turns out not to be.

Anyway, this is yet another example of a Norwegiam farmhouse ale where the hops are for protection against infection only. The aroma and bitterness is taken care of by the juniper.

Making the starter |

After we'd been running off for a few hours, Terje took some wort in a plastic bucket. Then he brought out a plastic box of pale gray flakes. This was the kveik, which Terje got from a friend in Hornindal twenty years ago, and has been using since. Terje collects the yeast after fermentation each time, and hands it to his father-in-law, who then cleans and dries it, before storing it in the freezer. We'd popped by his father-in-law in the morning on the way to the brewhouse, so the kveik would have thawed by now.

30 minutes later |

The flakes were poured into the bucket, and a kitchen towel put over the bucket. 30 minutes later we went back to the bucket and lifted the towel. The entire surface of the wort was now a brown porridge-like layer covered with bubbles. "In Hornindal we call this 'mariaue'," says Terje with a grin. (Note what he's saying: Hornindal dialect has a specific word for "yeast starter.")

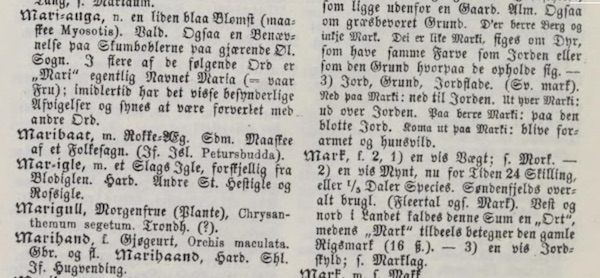

Ivar Aasen's dictionary, 1873 edition (1850 ed. has different text) |

This word confused me for a long time. Literally, it means "mari's eyes". But who is "Mari"? It's a common woman's name, but that makes no sense. Ivar Aasen's dialect dictionary from 1873 provides the answer: he thinks it's derived from the Virgin Mary. So this is actually "Mary's eyes". Later I saw that Odd Nordland was of the same opinion. In all likelihood this means the word is very old. It might well go back to medieval times.

But back to the yeast. For it to go from dried brown flakes to visibly fermenting in 30 minutes is not normal. In fact, it's astonishing. I saw something similar at home when I was growing it for our first recreation attempt. I took a bowl of water, poured the hard, gray flakes in, and put plastic foil over it. At this point the bowl was a little over half full. I then started measuring out malt powder, yeast nutrition, etc. When I turned back to the bowl I was startled to see a thick gray goo, almost like bread dough, straining at the plastic foil, seemingly trying to crawl out of the bowl.

Cooling wort |

As the milk cans were filled with hot wort from the running we took them outside and put them in a plastic bucket. The garden hose was pointed into the bucket and left running, which cooled the milk can quite rapidly. When the wort reached about 30 degrees we poured it into the fermenter. This was a big, square steel vessel of 400 liters, originally a milk container from when the farm had cows. It's insulated, which in Terje's opinion makes it perfect as fermenter, because then the wort will stay at 30 degrees during the running, and the fermenting wort will stay warm.

Finally, once we had all the wort run off and cooled, we were ready to pitch. Terje pitches at 30 degrees. He pitched at 27 once, but that beer didn't taste right. It had "kaldegangssmak", he says, which translates as something like "cold fermentation flavour". So now he sticks strictly to 30.

Once all the wort is run off Terje pitches the contents of the plastic bucket into the fermenter, and we're done. All that remains is some cleaning and tidying up, then we go back to Terje's house. Later that evening we come back to check on the fermentation. Three and a half hours after pitching there's a thick hat of foam in the fermenter. We taste the beer to check that it's OK, and in my mouth it's as warm as blood. Tastes fine. In the car on the way back down I can feel my stomach rumbling.

The story doesn't end here, of course. Terje had kindly invited me to stay until "oppskåka", the traditional party when the beer has finished fermenting. Since that was only two days later, I accepted. But we'll cover that in a later blog post. This one is already plenty long enough.

However, note what I'm saying here: primary fermentation takes only 48 hours. After that the beer is kegged and put in the cellar. This may sound crazy, but it turns out to be a key part of how the beer is brewed. When I made a second attempt at replicating it we let it ferment for a week (a work trip got in the way), and it came out too dry, too thin, and too low on carbonation. Also, the light diacetyl flavour was lost.

Fermenting away |

Recipe

Terje's recipe is simplicity itself. For 120 liters of beer, use 300 grams of Saaz hops. The grist is 25 kilos of pilsner malts and 25 kilos of pale malts. For Christmas, use a little more malts. The juniper should be only the thin branches, and don't cram the kettle full of it.

Boil the juniper a little while, then let the infusion cool down. Mash at 74 degrees for an hour to an hour and a half. You have to consider for yourself how to emulate the running; I'm not sure what the temperature was then. Run the wort through a bag of hops, then cool to 30C and pitch.

Terje ferments for 48 hours. When we tried to replicate this recipe we found that this actually matters for several different reasons. So you should aim for a short fermentation, then store the beer cool. The flavour will be affected by whether you store the beer at 4-5C (sweet, flat) or 10-11C (drier, more carbonation). OG was 1075, FG 1018, for a strength of 7.5% ABV.

As for what yeast to use: God alone knows. You can forget about buying a yeast that's even close to Terje's mix of 8 kveik strains plus bacteria. Well, that is: you can get a blend of the eight strains from NCYC, but not the bacteria. I'm working on finding a yeast bank that's willing to store the bacteria as well.

Similar posts

Brewing in Morgedal

The farmhouse survey showed that brewing in Telemark was still alive in the 1950s, but for a long time I thought it had died out

Read | 2015-10-29 14:00

Oppskåke

In older times there were a whole host of detailed social customs around the drinking of beer, but the only one I'm aware of that has survived into the present day is oppskåka

Read | 2016-02-14 12:45

Hornindal: interviews and collecting kveik

Terje learned to brew from his uncle when he was 16, while helping him on the farm during the summer

Read | 2016-01-03 14:15

Comments

Eric Ponce - 2015-12-26 14:12:57

Hello Lars, My name is Eric Ponce. First of all, great blog and I am glad I found it. I am the lead Brewer running the oak aging program at a brewery in Chicago called Goose Island. I am planning a personal trip to Norway in March of 2016. I am hoping to visit breweries, wineries or any traditional makers of alcoholic drinks in Norway. Possibly meeting you over a drink and conversation as well. Can you help with suggestions and an itinerary for 5-7 days in Norway. I am thinking that I would like to see the lofotene islands as well as hopefully northern lights and get a fishing trip in as well.

Thank you for your help and looking forward to your reply.

Cheers and good health

Hi - 2015-12-26 14:36:54

Awesome post, thanks for that. They're always a nice read.

Two thoughts which might be a bit of a big leap and are probably wrong...was there any bread yeast in the different strains? I'm pretty sure that they've modified that type to give the bread faster rises, I'm not sure if that would affect how fast the beer appeared to have fermented.

I was also wondering if there was any way to secure the hop bag inside of the tun while doing the mashing to act as a filter?

Lars Marius - 2015-12-26 14:45:11

@Eric: Thank you. I'll reply to you in private email.

@Hi: Thank you. :) NCYC didn't try comparing the yeast with Norwegian bread yeast, so I don't know if there is any commonality. It may be that it behaves like this because it's always top-cropped. Most of the kveiks tend to be very fast fermenters, since the brewers collect it early and have very short fermentation times (1-3 days).

The mash tun already has the rustesko and a bunch of juniper, so it doesn't really need any more filter. I know some people (elsewhere in Norway) would put the hop flowers in the mash.

Hi - 2015-12-26 15:55:51

Thank you very much for the quick reply and answers! Very interesting!

Looking forward to your next post, happy holidays :).

Dan ABA - 2015-12-26 16:58:34

Great post as always, Lars. A couple of questions for you. How long do they store the beer cold before serving it? Also, do you have a link to the cleaning and drying process that the father uses?

Thanks, Dan

Lars Marius - 2015-12-26 17:10:03

@Dan: Thank you. :)

The brewer himself has been known to say that the beer is best at "the oppskåke", meaning 48 hours after brewing. Of course, he probably keeps 20-60 liters for himself, so it takes a good while to drink it all. I'd say it takes 1-2 months at least before it's all gone. But there's no "store-before-serving" period. I had the beer at the oppskåke and while I didn't think it's as good as after it's matured a 1-2 weeks, it's really good even then.

As far as I know, nobody's ever written down or in any way documented the cleaning process. From what I gathered, the cleaning is the usual process of putting the yeast in water, then draining off the non-yeast part. This is repeated a few times. The yeast is then smeared on baking paper in a room in the cellar. Once it's dried into a thin (3-4mm) crust you can just crush it by folding the paper and drop it into a small plastic box and stuff it in the freezer.

(So much in farmhouse brewing, the solution to what appears to be a tricky problem turns out to be almost embarrassingly straightforward.)

pricelessbrewing - 2015-12-26 21:02:36

Wonderful as always Lars, keep this up.

Would love to read more about the yeast part. I know a couple homebrewers that dry their yeast out and store it in the fridge/freezer. For the most part they seem to make starters, decant as much liquid as possible then dry the yeast on lab paper in the fridge. I believe it's refereed to as dessication? Impressive to see this done in such an old school brewing tradition.

Roger - 2015-12-26 21:57:22

Hi guys, Terje and my father has been brewing this beer since early 90s (my grandfather stopped back in the 60s when pilsner was readily available). I recently got interested in this beer, after I started a modest hobby of brewing modern beer. Raw ale is something of an acquired taste, because its so different from what we think of as beer. The mash temp is high, so its also quite sweet, and no hop bitterness. Terje has been brewing for weddings for close family for years. This is tradition. But hes been soldiering on by himself a lot, so I think he appreciates anybody thats interested in this tradition. Think about it, a hundred years ago, every farm brewed in the region, now you can count them on one hand. And I am sure he will love to share his knowledge with anybody interested. If you are interested in the ceremony around the beer, it is quite anti-intellectual. Brewing beer was for parties. And being fermented at 35 degrees celsius, the pint warms your hand even in the summer :)

Lars Marius - 2015-12-27 04:39:15

@priceless: Thank you. I don't know what more to tell you about the yeast, really. I plan to try out the washing and drying process myself, and document it on the blog. It's called desiccation, yes. I know some people have been using hot air fans and all kinds of tricks. This method seemed pretty straightforward.

@Roger: Thanks for adding some extra detail. :)

merryn dineley - 2015-12-27 06:19:36

I enjoyed reading this. I shall have to read it several times, though, because there is so much detail. However much I learn about brewing, there is always more to learn. :-)

Happy New Year to you Lars!

Luke Corbin - 2015-12-27 17:54:42

Another sensational article Lars. With every post you contribute to applied beer history in the English language. Don't forget to tell Terje he is a celebrity now.

Keep up the great efforts!

Ben Godfrey - 2015-12-29 19:04:54

Love this! I love brewing traditional Finnish Sahti and this is VERY close to the same beer and procedure. Thank you very much to both you and Terje for posting this and sharing his recipe with us.

Jacob - 2016-06-19 04:24:06

Hi I brewed Kveik Yesterday and wooop full fretment after 4 hours. I wonder about the end of fermentation, presumably after 48 hours/ 2 days. Is it then going to be tapped to bottles or just moved to a secondary tank for maturing, and later bottling (maybe with a little yeast to help the karbonation on)?

Thanks for an interesting blog.

Lars Marius Garshol - 2016-06-19 04:27:33

@Jacob: The farmhouse brewers usually don't bottle. So after 48 hours (or 4 days or whatever, depending on which brewer it is) they transfer to the tank they're going to serve the beer from. At this point they consider the beer ready to drink, and will start drinking it.

They generally only bottle from the tank if they're going to take the beer with them or give it to someone. When they do it tends to be plastic bottles, which I think is a good idea, because this beer can easily start fermenting again. That's a lot safer in a plastic bottle. :)

Yannick - 2017-04-15 12:48:55

Thanks for this very interesting blog. I am French and after reading your blog, I would like to test the brewing of a Norwegian Farmhouse with branches of Junipérus. I will use the yeast "Sigmund's voss Kveik". Do you think that for a 20-liter brew, 2 kg of juniperus branches will be enough? Yannick

Lars Marius Garshol - 2017-04-15 12:56:22

@Yannick: Thank you! Yes, 2 kilos should be enough, and maybe even a bit much. Probably even 1 kilo might be too much. Look at the photos here, of how much juniper there is in the kettle.

Yannick - 2017-07-18 17:08:27

@Lars: My test of norwegian Farmhouse Ale, with the yeast "Sigmund's Voss Kveik". Interesting experience that I will revive. On the forum of the french site "Brassage amateur" https://www.brassageamateur.com/forum/ftopic30666.html

Coleman Carleton - 2018-10-27 19:02:46

I'm dying to know if the bacteria strains were identified? Bacteria in brewing that can provide complex aroma and flavor is something I've never seen. It's either Pediococcus and Lactobacillus adding lactic acid for some lemony/yogurt character and sourness or Acetobacter in Flanders ales adding a vinegar-like acetic acid and sourness.

Coleman Carleton - 2018-11-10 22:31:57

Actually, nevermind - I was able to get that info and culture from Richard at Escarpment!I do have some other questions though! When the beer is fermenting in the former dairy tank - is the lid left open for an open fermentation or was it closed? Also for the most complex flavor are you storing the bottles cool (10-11 C) or cold (4-5 C)? Is it safe to store the beer in either of those temperatures in glass bottles? I'd assume the yeast wouldn't continue any activity at cold temperatures and minimum activity at cool temperatures.

Lars Marius - 2018-11-10 22:48:22

@Coleman: Apologies for not replying to your first comment. I've seen several genera of bacteria mentioned by now by the microbiologists. I'm sure they're right, but it doesn't tell us much. Imagine wanting to know what yeast ferments a beer, and they tell you it's Saccharomyces, Nakazawaea, Candida and Brettanomyces. That's all true, but it's not going to tell you what the beer tastes like.

Terje closes the lid. I'm not sure what temperature he stores the plastic canisters at, but I assume 4-5C. They would explode at 10-11C. I would be hesitant to use glass for this type of beer, to be honest. The farmers generally use plastic.

At cold temperatures you're pretty safe, until you make a mistake, and then suddenly you've made a hand grenade. My advice is to stick to plastic, or a steel keg with a safety valve.

Bogdan - 2018-11-12 11:59:10

Some hop oils are common with pine/juniper needles.

John - 2019-04-02 11:27:50

Lars, I am really fascinated by your blog. I just ordered some Gjernes #1 Kveik from a guy (Hope its not the commercial stuff). At this point I dont intend to make traditional beer. Rather my own style (maybe you can consider me a Farmhouse brewer lol). But I do want it carbonated. At some point I am very interested in brewing with juniper and rather traditional, but for now I am just looking for a workhorse that can handle high gravity wort really fast, while producing interesting aroma.

My question: Does the 3 days stable FG reading still apply with this yeast? Or must I really worry concerning glass bottles even after hitting target FG? You did mention spontanious fermentation in these comments.

Lars Marius Garshol - 2019-04-04 18:33:55

@John: Sigmund generally racks the beer to cask after 4 days. The yeast can ferment at fridge temperatures, so if you're going to store it in a risky container then I would go with 3 days stable, yes. As you get more experience with the yeast you can probably skip that and just look at the FG.

The yeast is not diastatic, so once FG is stable it will behave much like other yeast, except that it tends to flocculate really hard and stick to the bottom. So getting it to carbonate in the bottle/keg can be tricky.

Pablo Cúneo - 2019-04-29 18:20:47

Hi, Lars. I want to consult about the convenient fermentation time and about the final density. I made a recipe for Maltol and I'm fermenting it with Laerdal 3 days ago at 32ºC. It is still fermenting and the current density is 1,006 and my estimate was 1,017. I started with a density of 1.067.

Is that final density normal? Should I finish the fermentation before? It does not feel sweet like in the first day and has very little body obviously. It is quite dry.

I would appreciate some ideas. Thank you.

Lars Marius - 2019-05-01 08:25:53

@Pablo: An FG of 1.006 is too low with kveik. You need a diastatic yeast to get this low, and kveik is not diastatic. So your fermenting beer contains something more than just kveik. I don't think there's much you can do about it, except get a new kveik culture for the next brew.

Tbrew - 2019-05-10 06:05:43

@Pablo, @Lars:

An FG of 1.006 is possible without the diastatic yeast, depending on the mash temp and grain bill and hop usage (hop creep).

But if the mash was at a normal high temp, Lars is probably right.

Mike Kelley - 2019-07-02 20:38:16

U.S. homebrewer here, in Fort Worth, Texas area.

I only recently learned of kveik, but it seemed interesting so I bought a packet of Omega's Hornindal from my local brew store (Stubby's Texas Brewing, shout out to some really good guys) and set about making a batch. I'm a lover of traditional methods, but I also love innovation, so I modified an Imperial Stout recipe and got to work. I wound up with 3.5 gallons of 1.109 OG (post boil, not a raw ale recipe) and pitched a starter I made from second runnings.

As expected, the starter showed about an inch of kreusen within 30 - 40 minutes on a stir plate. After I pitched (93 F), my airlock was bubbling happily within about 90 minutes or so. The off-gas smelled about halfway between generic citrus and bananas. The banana aroma increased significantly over the next 12 hours, and the citrus aroma disappeared in that time. Less than 48 hours after pitch, off-gassing stopped completely. There was a heavy scum on top of the brew and the citrus / banana aroma was completely gone. I wasn't able to keg for another 14 hours.

Final gravity at keg time (maybe 66 hours post-pitch) was 1.030, which I calculate at 11.7 ABV. I tasted a sample, and while the grain flavors came through just fine, I didn't get much of the yeast flavor. No citrus / bananas at all, but there was a noticeable mushroom flavor. The beer is at least as good as any of the local professional examples I've tried, but I think the grain masks a lot of the yeast contributions.

Grain bill and hop additions:

5.5 lbs Pilsner 5.5 lbs Wheat 1.5 lbs Black Patent 1.5 lbs Chocolate 0.5 lbs Special B 0.5 lbs Caramunich 0.5 lbs Pale Chocolate

3.2 oz Hallertau (not a noble variant), 90 minutes.

Mashed for 5 hours at 156 F, then boiled for several hours til I hit my target gravity. Crash and pitch.

One of the local microbreweries here allows homebrewers to bring in their beer for tasting. If the brewmaster likes the beer, he invites the homebrewer to do a batch at the brewery. I'm going to tweak this recipe a bit over the next few months and bring it to them later this fall.

Anyway, thanks for recording and sharing your knowledge of traditional brewing methods in northern Europe. I've learned a lot reading this blog.

Jason L - 2019-11-21 23:03:46

I am trying to brew this based off the Terje Raftevold’s kornøl recipe you posted in BYO. I want to stay as close as possible to the original, with exception of using juniper berries and some spruce tips instead of common juniper. You say to start mash at 165 and in 1.5 hours should be 158. I assume this is without any insulation in the mashtun. I use a cooler for a mash tun and would normally expect not much drop. Wondering if you or anyone else here had experience with/advice for this setup?

Maybe mash longer with the lid off but covered with towel to let heat escape? I am afraid to mash any lower to start with because pasteurization is needed for no boil.

Lars Marius Garshol - 2019-11-22 12:16:58

@Jason: How much the temperature is going to drop off will depend on ambient temperature, the size of your batch, and the mashtun. So it's not really possible to say anything very general about it. I would not worry too much about ensuring the temperature sinks. 74C seems to be a good mash temperature from my own experiments.

I would take care to sparge with boiling or near-boiling water, though, to ensure you deactivate the enzymes. It's good for hygiene, too, obviously.

Jason L - 2019-11-22 13:47:39

@Lars: Thanks! I thought the lower end temperature was important to ensure enzyme action, but from what you say it is incidental, so I will start at 165 and won't worry about it. Pre-ordered your book in English. Can't wait to learn more!

Jason L - 2020-01-13 22:14:13

@Lars: I wanted to provide some feedback and had a couple more questions...

I made the mistake of adjusting the recipe for my normal efficiency, but with less water being used (no boil-off) I should have known better, so I came up short on OG and less that 60% efficiency. Maybe I sparged too fast.

I was using Omega Yeast Hornidal and this was by far the smelliest fermentation I have ever had. Terrible sulphur smell, but no sign of infection. Is that normal for Kveik?

Second, the final product has a distinct corn smell and taste. Not unpleasant, but very noticeable. I assume this is DMS. Is that a normal part of the flavor profile since there is no boil to drive off DMS?

Malts were continental Pilsner and Pale malts and I was able to find some fresh Juniper to use, though I was very conservative with it and I don't believe I can taste it so I should have used more.