Svein, maltster and brewer

The såinnhus (malt house) and brewery |

At first glance it looked like any house in the area, a two-storey wooden house. At second glance, there was something odd about it. There was no garden, and very few windows. It looked oddly functional, and not very homely. Sure enough, Roar pulled the car off the road, parking right in front of the house. So this must be a såinnhus (malt house). (This is the second part about the Stjørdalen visit in January 2016.)

We were met by Svein Nygård, the informal leader of the maltsters and brewers who use the house. They were 10 brewers who formed an association 7-8 years ago, and then built the house together. They did all the work themselves, but it still cost about 13,000 euros, he says. They're fewer brewers using the house now, which worries him. He's thought about putting in an ad in the local paper to attract "young blood."

The malt kiln. Fireplace at the bottom. The smaller wooden box on top is the sprouting frame. It's taken off when the kiln is used for drying. |

He takes us to see the malt kiln. It looks exactly like the other ones I've seen. The process is also the usual one: first steeping the barley, then sprouting it in the wooden box that lies on top of the kiln, and finally drying on the wooden boards on top of the kiln. He says the distance from the fireplace (kjerringa) up to the planks is important, in order to get the right temperature without setting fire to the planks. Because the drying lasts several days the risk of fire is very real, and it's necessary to always keep an eye on the process. Svein says that if the wooden boards start making a creaking sound that means you're approaching the danger zone and need to reduce the fire.

Svein next to the kiln. The planks on the right are the sprouting frame. The perforated boards used to dry the malts are taken off. |

We leave the malting part of the building, and head over to the brewery. Svein heads off to fetch something, and for a few minutes we're at a loose end, looking around by ourselves. Amund finds a pile of books on home brewing. "Dangerous literature," he quips. I see what he means. What if these guys read them and discover that they've been doing things all wrong, and start modernizing their brewing? It's happened before.

The key part is a combined kettle and mashtun. Svein explains that they built it from two pieces of concrete pipe, and a kettle from a US army kitchen. At the bottom of the kettle is a false steel bottom with lots of little holes. They've added a steel pipe for the lautering, and cut a hole to make an opening for the fireplace. The door is from an old cast-iron oven, which they've welded onto a steel frame in the opening. The two sections of pipe were uncomfortably tall, so they cut off the top 10 centimeters of one of the pipes.

Svein next to the mashtun. Note the vertical crack in the concrete at the top. |

The way Svein describes it you'd think they cut concrete and weld steel every day, and that's probably not totally wrong. As we saw with Staffan on Gotland, farmers are used to modifying and adapting machinery, and building their own gear when they need to. It's really an ingenious piece of work that covers the entire brewing process in a single piece of kit.

Svein starts by laying the strainer bottom: first juniper branches, then uncrushed malts, and finally crushed malts on top. He pours on water, then starts the fire, gradually heating the mash until it hits 78 degrees. At that point, he says, the crack in the concrete starts widening, so he doesn't need a thermometer to hit the right temperature. He then runs off the wort, and pours it back on, repeating the cycle until the beer clears.

At some point he adds syrup and sugar to bring the strength up a little, but other than that it's 100% home-made malts. He's used a Norwegian barley variety called "Tirill". That's the same one Roar Sandodden and Morten Granås use.

Finally, he transfers the beer to the fermenter. So this is actually a raw ale, but different from the ones in Hornindal in that Svein mashes in the kettle. That's a method that was common in eastern Norway, but has mostly died out.

The fermenter is a repurposed milk container that has cooling built in, so they use that to cool the wort down to fermentation temperature. The kveik has died out in Stjørdal, so Svein uses the Idun Blå bread yeast for his beer. He says he always uses exactly one cube, regardless of how large the batch is, and it can be up to 300 liters. He pitches at 22C, and lets the yeast raise the temperature to 26-27, then racks the beer after three days.

Svein serving Martin beer |

And now it's time to try his beer. Svein brings out a large plastic jug. It doesn't look very professional, and our hopes don't exactly rise when he says this one got overheated during fermentation. The temperature rose all the way to 32 degrees before he discovered what was going on, and used the cooling in the vessel to bring it under control.

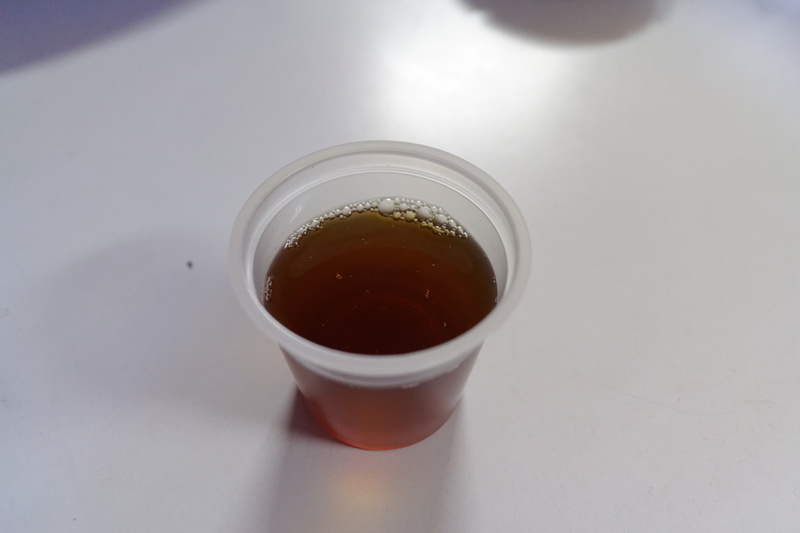

The beer |

Svein pours the beer into little plastic cups, where it looks rather like the ones we had the night before. It's pretty sweet, with powerful alder smoke aroma and a clear herbal juniper flavour, and very clean in flavour. It's a lovely beer. There is some heat, and I suspect the beer is quite strong. So I ask Svein, and he says "yeah, maybe I added a bit much sugar this time." He doesn't seem to know, or care, how strong the beer is.

Usually, raw ale is hazy, so I ask him how he manages to get this one so clear without boiling. "I don't know," is the instant answer. Then he bursts out laughing so his whole body shakes. "Wasn't that a good answer," he chuckles. Then he says some of the others want to get a copper kettle so they can brew "the old way," with boiling the wort. So clearly he used to boil, but now he's switched to raw ale. That's quite unusual.

I ask him why he stopped boiling. "Time," he says, tersely. The new approach is much faster, he says. And that's certainly true. When home-brewing, not boiling shaves off at least an hour and a half from the brewing process, and when brewing 300 liters the difference must be even greater.

Svein's malts |

But this, it turns out, is not the only reason. Svein says he used to have problems getting the carbonation right. "I've researched this," he says. When you scald a pig, you need to make sure the water is only 80 degrees, since otherwise the hairs will be very difficult to scrape off. If you boil, you get "this bad steam, and that kind of burns the skin." He continues about the bad steam a little, but I kind of lose the plot, and he seems to lose faith in his own argument, too, so he ends abruptly with a resounding "anyway, that's just logical!"

He asks if we want a second cup, and we eagerly agree, as the beer is so excellent. The talk starts drifting away from brewing onto other subjects. It turns out that Svein works as a lumberjack at least part of the time, and he shows us a horrific wound on his leg that he got when his forestry vehicle overturned as he was transporting a huge log. He survived by keeping his wits and timing his jump out of the vehicle as it was rolling repeatedly, but didn't get away completely free. It looks like most of the flesh on his leg must have been torn off, but he just laughs when talking about it.

The talk and laughter runs on for a while, until Svein offers us a third cup. I'm about to accept when the others remind me that Martin and I are supposed to be giving talks in not that many hours. I'd completely forgotten and feel kind of sheepish. So we realize we have to move on if we're going to not be late for the rest of the day. We thank Svein and make our goodbyes before driving off again.

Similar posts

Voss - farmhouse ale central

We'd booked a camping cabin in Voss, but because of confusion over the booking, we were moved into a huge house with lots of rooms instead

Read | 2014-07-20 15:32

Traditional Norwegian homebrew, finally

I was recently invited to give a presentation on Topic Maps at Vestlandsforsking in Sogndal, as part of their 25-year jubilee seminar series

Read | 2011-04-03 10:18

Dånnåbakken såinnhuslag

They call themselves Dånnåbakken Såinnhuslag, the group of 4-5 brewers and malters who share one brewery and malt kiln

Read | 2017-05-07 14:55

Comments

Alec Latham - 2017-03-19 16:34:03

Love the quip about it being dangerous to leave literature about home brewing out. Another very informative post.

Wilbur - 2017-03-20 04:23:38

Lars,I love hearing about this, thank you for exploring this part of brewing. I'm in Illinois, I'd like to get a better idea of traditional Norwegianian beers. Are there any commonly distributed commercial examples?

Lars Marius Garshol - 2017-03-20 08:32:35

@Alec: Thanks! Yes, I included that because I think it's actually an important point. Modern home brewing is threating to eradicate traditional home brewing, simply because the moderns have been unaware of the traditionals.

@Wilbur: Almost none of these beers are exported, or even available commercially in Norway. Unfortunately. I think the vossaøl from Voss Bryggeri is sometimes available in the Blind Tiger in NYC. It's conceivable that it might be available elsewhere, but I don't really know.

Roar Sandodden - 2017-03-20 11:50:41

@Alec: Alstadbeger is available in the US through the distributor B United. Both on tap and bottle. I do not know in which bars, but Untappd might give you an idea i guess

greg - 2017-03-27 05:18:16

Hi Lars, This is the only beer blog I read, thanks for doing it. I have one question though. Is "kjerringa" a word for the distance from the fireplace or is it the fireplace itself?

Lars Marius Garshol - 2017-03-27 07:40:53

@greg: Thank you, Greg! The maltsters in Stjørdalen today use "kjerringa" to refer to the fireplace. According to Odd Nordland, the term used to mean the stone slate directly above the fireplace.

Dan Pixley - 2017-03-28 22:14:30

Haha, now this guy sounds like a great character! I bet he is fun to get drunk with. ;)

Lars Marius Garshol - 2017-03-29 06:22:16

@Dan: Yes, that visit was a great experience. Would have loved to stay there drinking with him all night. :-)

merryn dineley - 2017-04-27 13:23:52

There are some great details about making the malt. I used to think that the malting floor was an important part of the process because this is how it was made traditionally in the UK. It is what I have read about and it is what the maltsters tell me. But these guys are sprouting the grain in wooden boxes, which is an effective way to make a small batch. This year I'm going to grow some barley (bere) and then I shall try and malt it. This is probably the way I shall do it, when I have enough grain to make malt.