Dånnåbakken såinnhuslag

The såinnhus (malt house) |

They call themselves Dånnåbakken Såinnhuslag, the group of 4-5 brewers and malters who share one brewery and malt kiln. From the outside the house looks like someone's home, except it's too small and doesn't have enough windows. Inside, the malting part of the house is bare and functional, but the brewery is more homely, with a kitchen and a table for gatherings. (This is the fourth part about the Stjørdalen visit in January 2016.)

The såinn (malt kiln), Ronny on the far right |

We're met by three members of the såinnhuslag, but the one who speaks the most is Ronny Hoseth. Their malt kiln looks exactly like the other ones we've seen, but is perhaps a little larger. After drying they remove rootlets and shoots by rubbing the malts on a frame of metal netting. It sounds like quite a bit of work, but they don't seem to mind.

Their brewing process is basically decoction: pour on hot water, run off wort, heat it in the kettle, pour back. Repeat until the wort that comes out is about 67-68 C. Since their ancestors won't have used thermometers I ask them how they came up with that specific temperature, and they say they got it from Morten Granås. Then they boil the wort in the normal way. They use 80 kilos of malt for 200 liters of beer, and add 0.1kg white sugar per liter.

The brewers. Kettle on the far right. |

Curiously, they use no hops at all. That seems to be a recent change, though. Ronny doesn't seem to like hops. He says "I tasted a beer the other day. That was well hopped, and that was a bitterbeer." I guess that means it was a craft beer of some kind, and clearly that wasn't Ronny's kind of beer.

They ferment with baking yeast, Idun Blå, which they pitch at 20 C. That sounds totally normal, but looking in their brewing log the entry for November 2015 has measurements of the temperature throughout the fermentation. It looks like this:

| 22/11-15 | ||

|---|---|---|

| 0945 | Buzzing nicely | 22C |

| 1345 | Buzzing well | 23C |

| 2030 | Buzzing nicely | 27C |

| 23/11-15 | ||

| 0600 | 30C | |

| 1500 | :-) | 30C |

| 1800 | Gonna be good | 28C |

| 2230 | 27C | |

| 24/11-15 | ||

| 0600 | 25C | |

| 0900 | 25C | |

| 1600 | Transferred to keg |

So clearly the temperature rises quite a lot when you're fermenting 200 liters of wort, and from the comments a temperature of 30 degrees doesn't seem to worry them at all. That's interesting. It also makes me wonder what kind of yeast that baking yeast actually is. Why doesn't it behave like normal brewing yeast? Where did the yeast company get it from originally?

The beer |

Ronny pours a glass for each of us, and hands it over. As usual, there's barely any head. Hazy deep reddish brown body. A fruity, light, fresh-tasting beer. Highly drinkable, despite the heavy smoke. Clean and refreshing, but perhaps a little sweet. Truly a lovely beer. Ronny says he thinks it's too sweet because they stopped fermentation a day too early, and remembering the temperature log that makes sense.

While I've described this style of beer as stjørdalsøl, the locals here don't call it that. These guys claim the brewing only survived in their part of Stjørdal, which is called Skjelstadmarka. So they insist on calling the beer "Skjelstadmarka maltøl". In Hegra, down in the valley proper, the locals claim the brewing only survived in Hegra, and so there Morten Granås calls his beer "Hegra maltøl". But the brewing clearly survived also in Skatval, so I don't buy any of these stories, and in any case the name "stjørdalsøl" is well established.

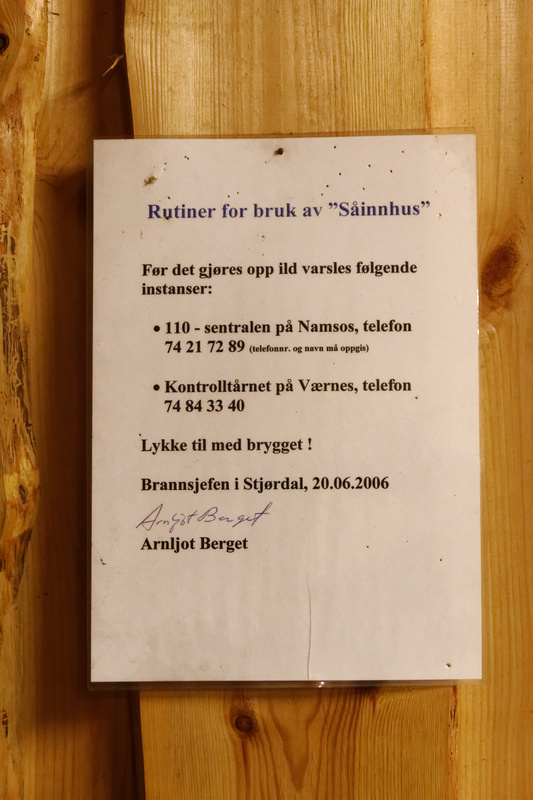

Fire procedure |

On the wall hangs a laminated sheet of paper, stating that before firing the malt kiln they have to call the local fire brigade and the control tower of Trondheim airport. It ends with "good luck with the brewing!" and is signed by the chief of the local fire brigade. The reason they have to warn is that drying the malts causes so much smoke that people (and airplane pilots) often report malt drying as fires, and this little routine saves the fire brigade a number of false alarms.

It's getting late in the day, and we have to visit another såinnhus before giving our talks, so we have to rush off. We thank the guys, then head back to the car.

Similar posts

Svein, maltster and brewer

At first glance it looked like any house in the area, a two-storey wooden house

Read | 2017-03-19 11:17

Stjørdalsøl — the tasting

During our 2014 farmhouse ale expedition, Martin and I visited Stjørdal, a region in Norway famous for the many farmhouse brewers who still make their own malts in the traditional way

Read | 2017-03-09 14:58

Alstadberger

Driving hurriedly on from Storli Gard, we arrived at the island of Tautra outside Trondheim late at night

Read | 2014-09-03 19:59

Comments

No comments.